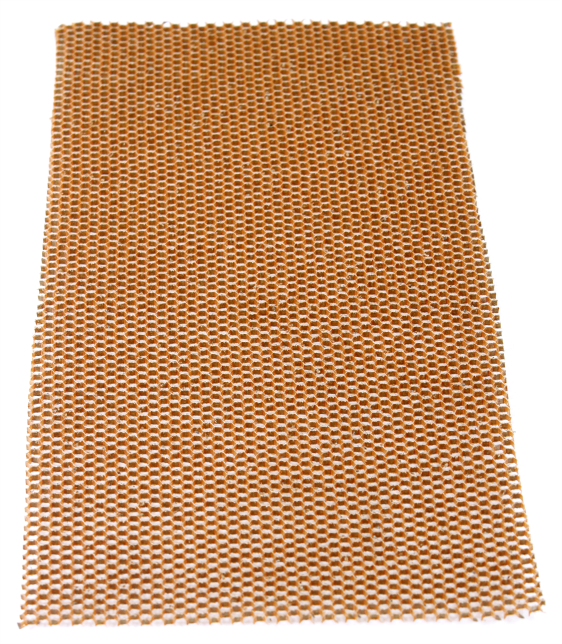

Honeycomb Core

- Home

- Product

Showing the single result

Product Description

Aerospace grade Non-metallic honeycombs are made by forming aramid paper, which is high temperature resistant, into a honeycomb shape and coating it with phenolic resin.

Hipex honeycomb is especially suitable as a core material for production of sandwich structures requiring significant FST performance and using high performance fiber reinforced composites as the facing material. It is designed to offer users and designers high strength-to-weight properties at relatively low cost.

Feature:

- Fire-retardant (self-extinguishing).

- Excellent dielectric characteristics, High strength to weight ratio, Corrosion resistance.

- High toughness and thermal insulating properties.

- Excellent performance against creep and fatigue; good thermal stability

- An enlarged cell layout that may be used to create basic curves.

- Compatibility with the majority of sandwich composite adhesives.

Application:

- Uses for sandwich panels.

- Variable densities for aircraft flooring according on level of duty.

- Leading and trailing edges of an aircraft.

- Interiors of aircraft, such as sidewalls, galleys, and ceilings, as well as VIP, business, and commercial interiors.

- Helicopter rotor blades.

- Fuselage elements and Cargo lining.

Technical specification:

|

Product

|

Density

(kg/m3) |

Stabilized Compression | Plate Shear | ||||

| Strength (MPa) | Modulus (MPa) | Strength “L Direction” (MPa) |

Modulus “L Direction” (MPa) |

Strength “W Direction” (MPa) |

Modulus “W Direction” (MPa) |

||

| AH-3.2-29 | 29 | 0.9 | 60 | 0.5 | 25 | 0.31 | 17 |

| AH-3.2-48 | 48 | 2.3 | 138 | 1.25 | 40 | 0.73 | 25 |

| AH-3.2-64 | 64 | 3.9 | 190 | 2 | 63 | 1 | 35 |

| AH-4.8-48 (OX) | 48 | 2.7 | 120 | 0.8 | 20 | 0.85 | 35 |

PRODUCT DESIGNATION:

AH: Aerospace honeycomb, 3.2: Cell size in Millimeter, 29: Density, OX: Over expanded.

*Available in customized sizes and packaging based on customer needs. Contact us. if you’d like further details.

Size:

| Thickness | Width | length |

| 2 MM to 100 MM | 600MM, 1200 MM | 2400 MM, 2500 MM |

Note:

- When handling fine fibrous materials, standard safety procedures should be followed.

- The use of clean, disposable inert gloves protects the user and prevents material and component contamination.

- All information is provided without warranty but with the assumption of accuracy. Users should decide for themselves whether a product is appropriate for their needs.