Perforated Release Film

- Home

- Product

Showing the single result

Product Description

Perforated release film basically used for removing helping material which are utilized in vacuum bagging technique. Hipex Group are leading manufacturer of perforated release film in ahmedabad, Gujarat , india. Release films is place over the laminate and disunite the laminate from breather cloth which has no relinquishment characteristics. Release films are often perforated in order to ascertain that any trapped air, volatiles or excess resin, which may compromise the physical properties of the laminate, can be abstracted. A variety of film alternatives with different perforation patterns are available to meet the different requirements for cure temperatures, thicknesses, tensile strengths, adhesion, and higher service temperatures.

Feature:

- Compatible with phenolic, polyester, and epoxy resin systems.

- High elongation and strength reduces tearing and bridging in corners, so less rework on resin rich corners on products.

- Wider films reduce seams yielding more expeditious bagging and safer cure for sizably voluminous components.

Technical specification:

Technical Specification Vacuum Begging film as per standards ASTM D 882

| Properties | Specification |

| Material | High density polyethylene |

| color | Light Blue, Pink |

| Elongation at Break | 380% |

| Tensile strength | >45 Mpa |

| curing temperature | 125°C to 130°C |

| Shelf Life | Unlimited at room temperature in original packing |

| Packing | Wrapping by air bubble roll on film and packaged into cardboard outer tube. |

Size:

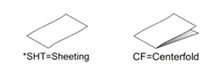

| Thickness | Width | Forms Available* |

| 0.0006 inch (15 µm) | up to 48 inches (1.22 m) | SHT |

| 0.001 inch (25 µm) | up to 60 inches (1.5 m) | SHT,CF |

| 0.002 inch (50 µm) | up to 60 inches (1.5 m) | SHT,CF |

PRODUCT DESIGNATION:

* Available in customized sizes and packaging based on customer needs. Contact us if you’d like further details.

Note:

- Storage at room temperature and Low moisture level.

- Due to film perforation, overlap shouldn’t be greater than 20 mm.