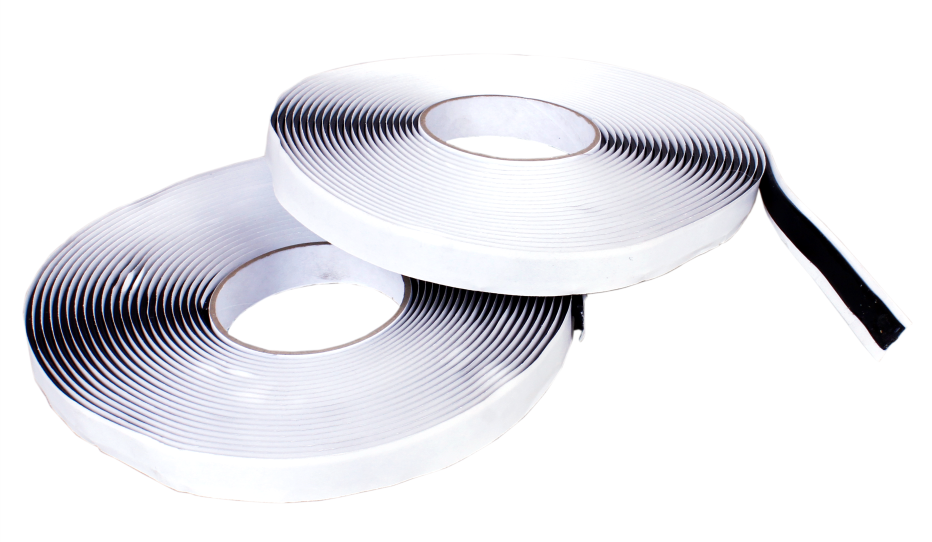

Sealant Tape -Low Temperature

- Home

- Product

Showing the single result

Product Description

Low temperature sealant tape ideally utilized in vacuum bagging technique for making small component of composite product where temperature does not exceed up to 300°F (150°C). It has high cohesive Strength and sealing capability, as well as adhesion to a variety of films and tooling surfaces. It is compatible with a wide variety of film types and implements surfaces of aluminum, steel, fiberglass, nickel and graphite etc.

Feature:

- Perfect for autoclave and oven cure cycles.

- It is extremely resistant to UV radiation. When exposed to direct sunlight, having one side laminated can help to maintain the material’s characteristics.

- It has good moisture and anticorrosive properties.

- Tape connects vapor barrier membranes and films in an airtight and vapor-tight manner because to its strong elastic and plastic capabilities

Technical specification:

| Material composition | Synthetic Butyl rubber |

| Color | Black |

| Elongation at Break | 400% |

| Maximum use temperature | 300°F (150°C). |

| Non Volatile Contents | 99.8 % at 100°C for 3 hours |

| Shelf Life | 12 month from date of Manufacturing. |

| Storage condition | Must be stored between -25°C to 40°C and away from heat,water, moisture & direct Sun light. |

Size:

| Dimension | *Packing |

| 1/8 inch x 1/2 inch x 10 MTR (3 mm x 12 mm x 10 MTR) |

32 rolls per case |

| 1/8 inch x 1/2 inch x 16 MTR (3 mm x 12 mm x 16 MTR) |

20 rolls per case |

Available in customized sizes and packaging based on customer needs. Contact us if you’d like further details.

Note:

- It is advised to remove the tape from the tooling or mould surface once it has cooled to room temperature for a clean removal.

- Before applying sealant tape, the mould surface has to be clean, dry, and clear of debris, oil, and other substances..

- Water, moisture, and direct sunshine should all be avoided.