Vacuum Bagging Film

- Home

- Product

Showing the single result

Product Description

Vacuum bagging film mostly used in composite industries. It is used to cover the whole mould surface, including all consumable materials for vacuum-sealing laminates. For meeting product quality parameters, vacuum bagging film is mostly utilized in hand lamination and VARTM (Vacuum Assisted Resin Transfer Molding). High elongation, high temperature nylon film appropriate for cure temperatures up to 410°F (210°C). We provide a broad selection of bagging film products with labor-saving features including welded wide format or custom forms.

Hipex Composite Pvt Ltd’s collection of high-performance vacuum bagging films ensures precision, excellence, and effectiveness. Our bagging films are offered as designed kits or roll stock.

Feature:

- A smooth surface devoid of pinholes or other imperfections, with good sealing abilities.

- It has excellent elongation, strength and flexibility.

- It is susceptible to variations in humidity, since moisture is utilized as a natural plasticizer.

Technical specification:

Technical Specification Vacuum Begging film as per standards ASTM D 882

| Properties | Specification |

| Material composition | Nylon |

| color | Yellow,Green,Blue,Red, |

| Elongation at Break | 400% |

| Tensile strength | >45 Mpa |

| Maximum use temperature | 410°F (210°C) |

| Shelf Life | Unlimited at room temperature in original packing |

| Packing | Wrapping by air bubble roll on film and packaged into cardboard outer tube. |

Size:

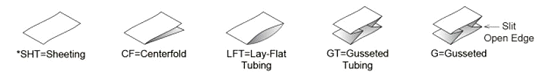

| Thickness | Width | Forms Available* |

| 0.0021 inch (55 µm) | up to 354 inches (9.00 m) | CF,SHT,LFT |

| 0.0025 inch (65 µm) | up to 354 inches (9.00 m) | CF,SHT,LFT |

| 0.003 inch (75 µm) | up to 354 inches (9.00 m) | CF,SHT,LFT |

| 0.0033 inch (85 µm) | up to 354 inches (9.00 m) | CF,SHT,LFT |

PRODUCT DESIGNATION:

*Custom size, thickness and length are available as per customer requirement. Please contact us for more information.

Note:

- Storage at room temperature and Low moisture level.

- Avoid using sharp objects while handling the film, keep fingernails cut when holding it, and clean the mould surface before applying it.

- Do not open the cardboard case until its application