Vacuum Infusion Flow Media

- Home

- Product

Showing the single result

Product Description

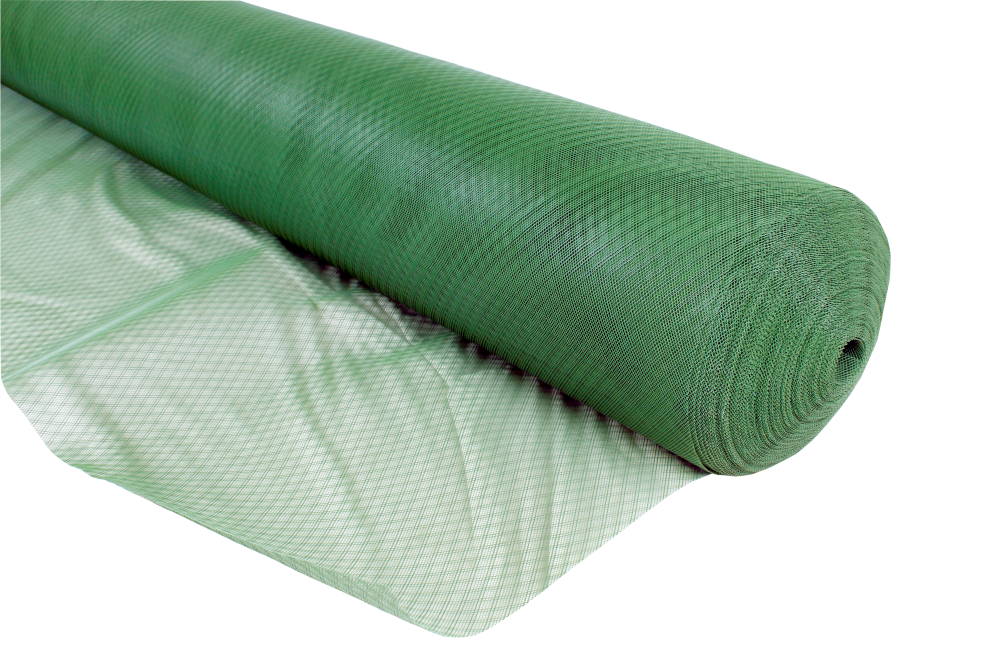

In the advanced composites industries, a polymer infusion mesh with a diamond aperture is employed. To ensure that resin flows evenly across the whole surface of the mould, it is set flat on surface of mold. Infusion mesh makes a space between the vacuum film and glass fabric laminate so that the vacuum pump may draw air into the laminate. It is often used in green color to improve the visually clarity of the resin’s flow across the surface of the mould. After composite laminate cured it is removed from the laminate.

Feature:

- It is easier to remove from the laminate because to its higher strength and elongation.

- Resin easily flow in the laminate due to its uniformly diamond hole size.

- As a result of the low profile and tight construction, it is intended to distribute resin effectively with minimum waste.

- The entire cost of the vacuum begging process is reduced with cheaper infusion mesh.

Technical Specification:

| Material type | High-Density Polyethylene – HDPE |

| color | Green |

| Tracer Yarn | Red, Black |

| Maximum Use temperature | 302°F (150°C) |

| Weight (g/㎡) | 150 to 250 |

| Melting temperature | 260 °F (127 °C) |

| Shelf Life | Unlimited at room temperature in original packing |

Size:

| width | Length | *packing |

| 47 inch (1.2 MTR) | 55 yard (50 MTR) | 1 Roll |

| 60 inch (1.5 MTR) | 55 yard (50 MTR) | 1 Roll |

*Available in customized sizes and packaging based on customer needs. Contact us if you’d like further details.

Note:

- The Hipex Composite Pvt Ltd advises testing before use because the maximum usage temperature depends on the time spent at the maximum temperature and is process-specific.

- Make sure the infusion mesh must be placed on peelply or release film. Don’t place on the direct to the laminate.