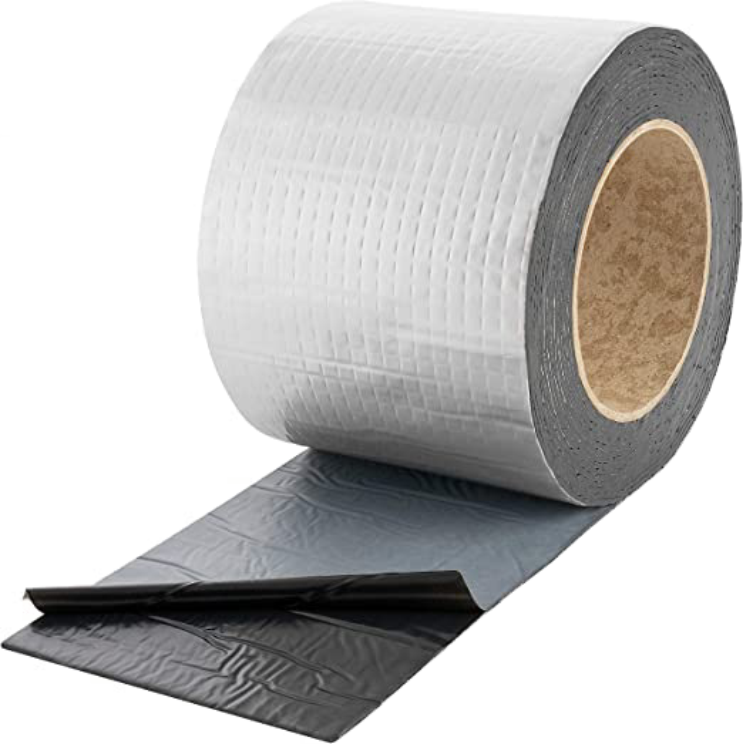

Butyl aluminum flashing tape

- Home

- Product

Showing the single result

Product Description

In India, we are the top exporters and manufacturers of butyl aluminum flashing tapes. A self-adhesive tape, Hipex Butyl Aluminum Flashing Tape is constructed of a butyl rubber compound, self-protected by a single-sided release paper, and the other side reinforced with aluminum foil. It comes in a variety of sizes. It has excellent adhesive qualities at low temperatures, can be applied in the cold, is waterproof, and has excellent heat stability. It doesn’t flow when heated and doesn’t exhibit oil migration. It is resistant to UV radiation and ageing. There are no solvents present.

Advantage:

- Excellent resistance to chemicals, the weather, and corrosion.

- Remains adaptable during the duration of its service life.

- Air tightness, high and low temperature resistance, water resistance, and dimensional stability are all outstanding.

- High tensile strength, outstanding elasticity, and excellent extension qualities.

- The Anti-Friction, Anti-Scratch, and High Temperature Resistance of Aluminum Foil Flame retardant, ultra-high bond, and ultra-strong adhesive that even works underwater.

Application:

- Materials including glass, steel, polycarbonate, wood, aluminum, PVC, industrial roofing, pipes, cable, refrigeration, and many other home uses may all be waterproofed, sealed, and joined.

Technical specification:

| Characteristic | Specification |

| Material type | Butyl rubber |

| Solid content | 99.90% |

| color | Black , Gray |

| Specific gravity | 1.5 ± 0. 15 |

| Protective backing | Aluminium |

| Service temperature | -20°C to 120°C. |

| application temperature | 0°C to 50°C. |

| water absorption | <0.5% |

| Metal particle | Nil |

| Shrinkage | Nil |

Size:

| Width | Thickness | Length* |

| 2 inch | 1.5 MM, 2 MM | 2.5 ft , 32 Ft |

| 4 inch | 1.5 MM, 2 MM | 2.5 ft , 32 Ft |

| 6 inch | 1.5 MM, 2 MM | 2.5 ft , 32 Ft |

Available in customized sizes and packaging based on customer needs. Contact us if you’d like further details.

Note:

- Application Surface should be spotless, dry, and free of debris like oil and dust.

- It is advised to use an appropriate primer to seal and stabilize the surface before applying the tape on porous surfaces.