Geosynthetic Clay Liners (GCL)

- Home

- Product

Showing the single result

Product Description

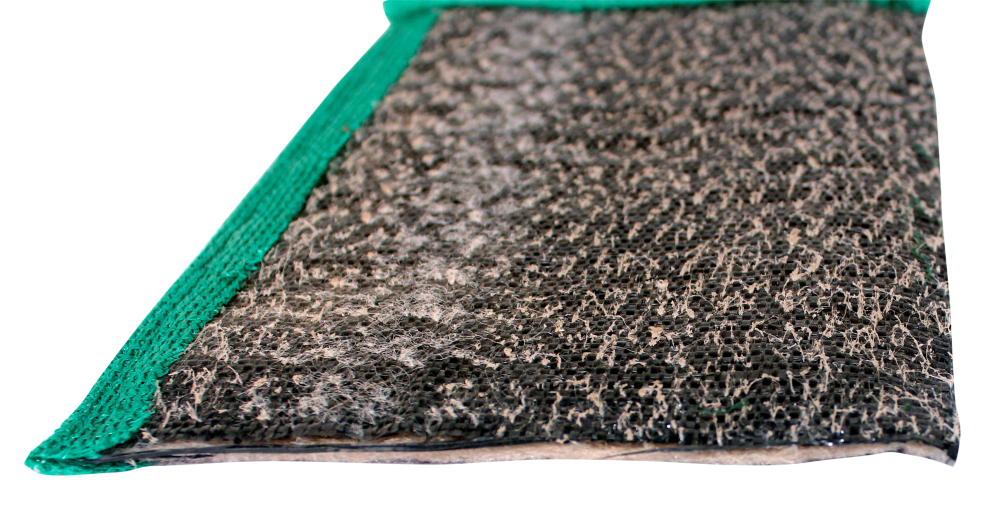

An intermediate layer of sodium bentonite powder is usually placed between two layers of non-woven geotextile that make up a geosynthetic clay liner (GCL), a mineral sealing mat that is manufactured by Hipex in Ahmedabad, Gujarat, India. A stitching procedure is used to link the two layers of geotextile (needle punched non-woven). With great internal shear resistance for a range of environmental confinement applications, this results in an utterly stable mat.

The high swelling capacity and low permeability of the bentonite provide an efficient hydraulic seal, while the geotextiles provide long-lasting resistance to physical or chemical breakdown in severe environments.

Hydraulic barriers against water and other liquid materials are created using geosynthetic Liner. Geosynthetic clay liner can take the place of compressed clay layers as a hydraulic barrier. The major benefits of geosynthetic clay coatings include their low cost, ease of installation, restricted thickness, and ability to decrease various settlements under the ground or on waste materials.

Advantage:

- It has resistant to shrinkage, strong, and durable.

- GCL are used above to defend against coarse gravel punctures.

- Changes in density, moisture, or clay content have little to no impact on GCL.

- It has excellent internal shear resistance for a variety of environmental containment applications.

Application:

- Canals, storm water impoundments, and wetlands.

- Landfill liners.

- Landfill caps.

- Mining.

- Ponds.

- Secondary containment.

- Highway and civil.

Technical specification:

Technical Specification Of Geosynthetic Clay Liner (Gcl), As Per Is: 10319

| Characteristic | Unit | Specification |

| Composite (GBR-C) | ||

| Weight per Square Meter | g/m2 | 3300-5200 |

| Peel strength | N/10cm | 35-65 |

| Longitudinal Tensile strength | kN/m | 11-12 |

| Longitudinal Elongation | % | <20 |

| Geotextile properties | ||

| Base Layer | – | Non-woven |

| Upper Layer | – | woven |

| Polymer | – | Polypropylene |

| Bentonite properties | ||

| Material type | – | Sodium bentonite |

| Melting temperature | °C | 1340 |

| Specific weight | g/cm2 | 2.6 |

| Free swelling capacity | ml/2g | >24 |

Size:

| Thickness | Width | Length Available* |

| 5 MM | 4 – 6 MTR | 50MTR,100 MTR Roll |

| 6 MM | 4 – 6 MTR | 50MTR,100 MTR Roll |

| 6.5 MM | 4 – 6 MTR | 50MTR Roll |

| 7 MM-10 MM | 4 – 6 MTR | 50MTR Roll |

Available in customized sizes and packaging based on customer needs. Contact us if you’d like further details.

Note:

- Protective packing should not be removed until the GCL is not required to be installed.

- The GCL has to be covered within three days after the installation.

- Storage on flat ground surface.