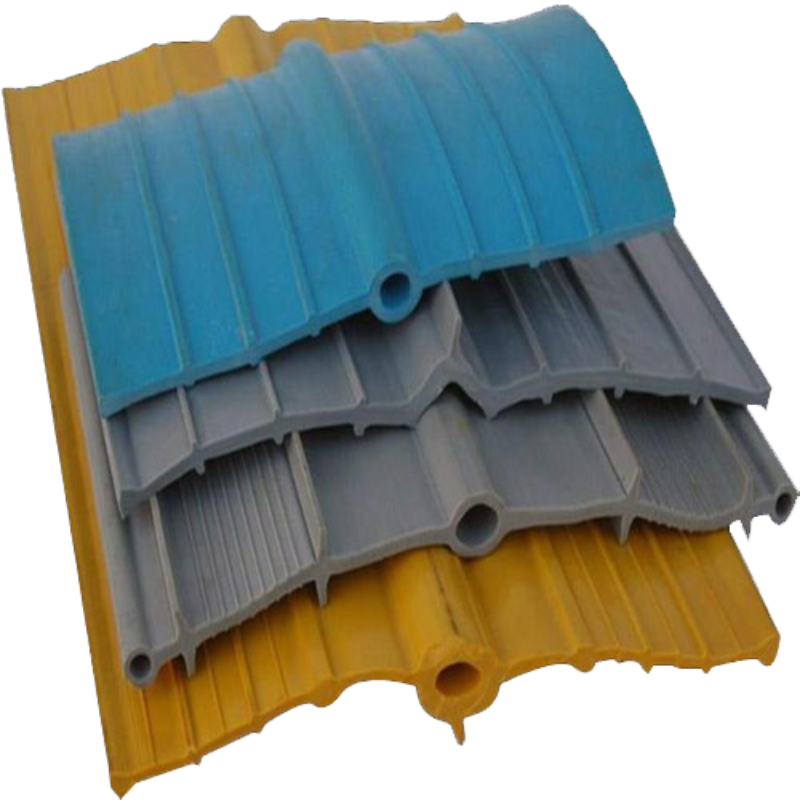

PVC Water Stopper

- Home

- Product

Showing the single result

Product Description

Our PVC Water stoppers are constructed of virgin PVC material, stabilized for light and heat (UV) protection, and protected against ageing, giving them a lifespan. Large concrete structures need a deep foundation to be stable and are created using many pours to relieve pressure or on top of already completed structures. This indicates that the entire structure would have many Cold Joints created by subsequent pours. Hydrophilic PVC Water Stops should be fitted at every junction to make the structure water tight since co-formed joints might lead to water seepage. The hollow central bulb provides the elasticity and flexibility required to accommodate joint extension and transverse motions.

Advantages:

- Outstanding natural elasticity and impermeability.

- Protect against hydrostatic pressure and water leaking.

- Completely devoid of material defects, is not brittle, and does not shatter when exposed to typical conditions.

- If placed properly, it won’t fail during natural joint expansion and contraction.

- An optional reinforced edge flange with brass eyelets makes it simple to wire the reinforcement.

Application:

- Public Utilities: For irrigation projects, water tanks, water filtration systems, swimming pools, sewage treatment facilities, clarifiers, dams, canals, reservoirs, and aqueducts.

- Buildings: For terraces, retaining walls, slabs, masonry joints, basements, foundations, and overhead & subterranean water tanks.

- Industries: Thermal and hydro power plants, chemical and waste treatment facilities, atomic reactors, shipyards, and docks.

Selection of appropriate PVC water stopper

Ribbed design: Used in situations where there is usual movement between membranes/layers and water pressure is applied on both sides, such as in contraction and expansion joints where a firm grip in the concrete is needed and when it is anticipated that the poured concrete would settle differently.

Dumbbell: Joints expand and compress when temperature variations are higher. The recommended water stoppers in these situations are dumbbell-shaped ones.

Kicker (surface type): These are installed externally in situations when the embedded kinds cannot be utilized due to interference from steel reinforcing.

We manufactured products in a variety of forms, including tear web, flat ribbed, split ribbed, split dumbbell, split dumbbell with centre bulb, and dumbbell with base seal as per customer needs.

Technical specification:

Technical Specification PVC Water Stop Seal as Per IS: 15058:2002 and IS: 12200:2001.

| Characteristic | Unit | Specification |

| Color | Black, white | |

| Tensile Strength | Mpa | 13.7 min |

| Elongation at Break | % | 285 MIN |

| Hardness | Shore-A | 65 Min |

| Water Absorption | % | 0.6 Max |

| Cold Resistance (at-25o | Visual | No Crack |

| Accelerated Extraction Test. | ||

| Tensile Strength | Mpa | 10.4 Min |

| Elongation at Break | % | 280 Min |

| Stability in effect of Alkalis test. | ||

| Weight increase at 7 days | % | 0.25 Max |

| Weight decrease at 7 days | % | 0.10 Max |

| Change in hardness at 7 days | Shore-A | 5 |

| Weight increase at 28 days | % | 0.40 Max |

| Weight decrease at 28 days | % | 0.30 Max |

| Dimension Change | % | 1 |

Size:

| Width | Thickness | Forms Available* |

| 6 inch (150 MM) | 5-6 MM, 8 MM, 10 MM, 12 MM | 25 MTR Roll |

| 9 inch (230 MM) | 5-6 MM, 8 MM, 10 MM, 12 MM | 25 MTR Roll |

| 12 inch (305 MM) | 5-6 MM, 8 MM, 10 MM, 12 MM | 25 MTR Roll |

Available in customized sizes and packaging based on customer needs. Contact us if you’d like further details.

Note:

- The water stopper’s overall width must not exceed the concrete’s thickness.

- It should not be less than half the width of the water stopper between the concrete face and water stopper.

- Water stopper width must be at least six times wider than the biggest aggregate used in concrete.